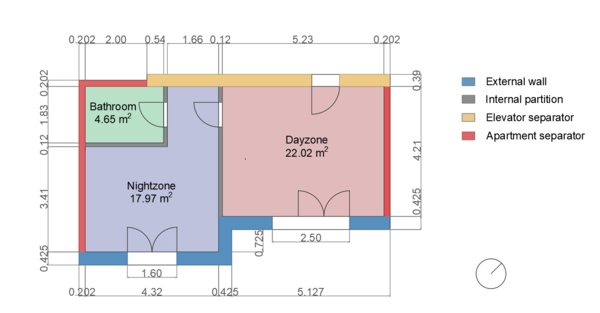

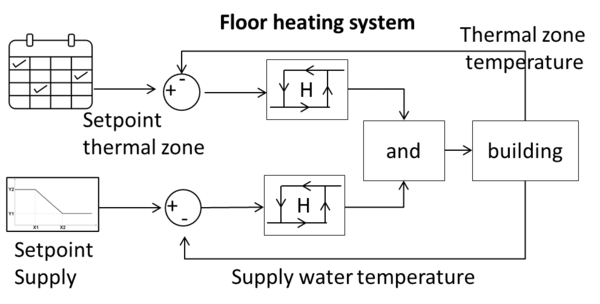

The building is a two room apartment model representing a real case study in Milan, which consists of two rooms and one bathroom. The bathroom and the nightzone are considered together in a single thermal zone. So in total, two thermal zones are considered. The aparment is a newly built heavy construction. The height of each room is 2.7 m, while the other dimensions are reported in the plan below.

The journal paper cited below shows a brief validation of the envelope model using experimental data. However, KPIs results may differ using the latest version of the testcase due to updates with respect to the manuscript version in terms of internal gains, schedules and air mass exchange between the zones.

Zanetti E, Kim D, Blum D, Scoccia R, Aprile M. Performance comparison of quadratic, nonlinear, and mixed integer nonlinear MPC formulations and solvers on an air source heat pump hydronic floor heating system. Journal of Building Performance Simulation. 2022 Sep 15:1-9. [url]

As can be seen from the plan, there are four different types of walls that, with the floor and the ceiling, constitute the boundaries of the thermal zones. All the geometrical and thermal characteristics of the various material layers are highlighted below.

| External wall | |||||||

| N | Description | x [m] |

k [W/(mK)] |

c [J/(kg K)] |

d [kg/m3] |

absIR [-] |

absSol [-] |

|---|---|---|---|---|---|---|---|

| 1 | Exterior plaster | 0.005 | 0.300 | 840 | 1300 | 0.9 | 0.6 |

| 2 | EPS 120 thermal insulation panel | 0.1 | 0.034 | 1250 | 23 | - | - |

| 3 | Masonry brick | 0.3 | 0.207 | 840 | 750 | - | - |

| 4 | Gypsum plaster | 0.02 | 0.570 | 1000 | 1300 | 0.9 | 0.6 |

| Internal partition | |||||||

| N | Description | x [m] |

k [W/(mK)] |

c [J/(kg K)] |

d [kg/m3] |

absIR [-] |

absSol [-] |

|---|---|---|---|---|---|---|---|

| 1 | Gyproc Duragyp panel | 0.0125 | 0.250 | 1000 | 1025 | 0.9 | 0.6 |

| 2 | Plasterboard panel (WALLBOARD 13) | 0.0125 | 0.250 | 1000 | 710 | - | - |

| 3 | Glass wool insulation panel (CTGS Par70) | 0.07 | 0.040 | 840 | 40 | - | - |

| 4 | Plasterboard panel (WALLBOARD 13) | 0.0125 | 0.250 | 1000 | 710 | - | - |

| 5 | Gyproc Duragyp panel | 0.0125 | 0.250 | 1000 | 1025 | 0.9 | 0.6 |

| Elevator separator | |||||||

| N | Description | x [m] |

k [W/(mK)] |

c [J/(kg K)] |

d [kg/m3] |

absIR [-] |

absSol [-] |

|---|---|---|---|---|---|---|---|

| 1 | Gypsum plaster | 0.02 | 0.570 | 1000 | 1300 | 0.9 | 0.6 |

| 2 | Concrete | 0.3 | 2.15 | 880 | 2400 | - | - |

| 3 | Glass wool insulation panel (Par45) | 0.045 | 0.038 | 1030 | 13 | - | - |

| 4 | Plasterboard panel (WALLBOARD 13) | 0.0125 | 0.250 | 1000 | 710 | - | - |

| 5 | Gyproc Duragyp panel | 0.0125 | 0.250 | 1000 | 1025 | 0.9 | 0.6 |

| Apartments separator | |||||||

| N | Description | x [m] |

k [W/(mK)] |

c [J/(kg K)] |

d [kg/m3] |

absIR [-] |

absSol [-] |

|---|---|---|---|---|---|---|---|

| 1 | Gyproc Duragyp panel | 0.0125 | 0.250 | 1000 | 1025 | 0.9 | 0.6 |

| 2 | Plasterboard panel (WALLBOARD 13) | 0.0125 | 0.250 | 1000 | 710 | - | - |

| 3 | Glass wool insulation panel (CTGS Par70) | 0.07 | 0.040 | 840 | 40 | - | - |

| 4 | Plasterboard panel (WALLBOARD 13) | 0.0125 | 0.250 | 1000 | 710 | - | - |

| 5 | Glass wool insulation panel (CTGS Par70) | 0.07 | 0.040 | 840 | 40 | - | - |

| 6 | Plasterboard panel (WALLBOARD 13) | 0.0125 | 0.250 | 1000 | 710 | - | - |

| 7 | Gyproc Duragyp panel | 0.0125 | 0.250 | 1000 | 1025 | 0.9 | 0.6 |

| Ceiling | |||||||

| N | Description | x [m] |

k [W/(mK)] |

c [J/(kg K)] |

d [kg/m3] |

absIR [-] |

absSol [-] |

|---|---|---|---|---|---|---|---|

| 1 | Ceramic tiles | 0.015 | 1.000 | 840 | 2300 | 0.9 | 0.6 |

| 2 | Concrete slab with additive | 0.064 | 1.000 | 880 | 1800 | - | - |

| 3 | Expanded polystyrene | 0.026 | 0.034 | 1300 | 25 | - | - |

| 4 | Isover fonasoft | 0.006 | 0.113 | 2100 | 450 | - | - |

| 5 | Light substrate | 0.105 | 0.100 | 1200 | 400 | - | - |

| 6 | Reinforced concrete (1% steel) | 0.230 | 2.300 | 1000 | 2300 | - | - |

| 7 | Gypsum and sand plaster | 0.200 | 0.800 | 1000 | 1600 | 0.9 | 0.6 |

| Radiant floor | |||||||

| N | Description | x [m] |

k [W/(mK)] |

c [J/(kg K)] |

d [kg/m3] |

absIR [-] |

absSol [-] |

|---|---|---|---|---|---|---|---|

| 1 | Ceramic tiles | 0.015 | 1.000 | 840 | 2300 | 0.9 | 0.6 |

| 2 | Concrete slab with additive | 0.064 | 1.000 | 880 | 1800 | - | - |

| 3 | Expanded polystyrene | 0.026 | 0.034 | 1300 | 25 | - | - |

| 4 | Isover fonasoft | 0.006 | 0.113 | 2100 | 450 | - | - |

| 5 | Light substrate | 0.105 | 0.100 | 1200 | 400 | - | - |

| 6 | Reinforced concrete (1% steel) | 0.230 | 2.300 | 1000 | 2300 | - | - |

| 7 | Gypsum and sand plaster | 0.200 | 0.800 | 1000 | 1600 | 0.9 | 0.6 |

These properties are defined in the model of each thermal zone respectively in the component matExtWal, IntWall,

ElevatorSep, AptSep, roof and slaCon. All the material layers are defined starting from outside to

room-side except for the radiant floor that requires the opposite order, as reported in the Modelica Buildings Library envelope user guide.

Considering the two glazing systems of the small apartment, they have the same construction and shading system, differing only in the dimensions. These characteristics are reported in the tables below.

| Glazing system dimensions | ||

| Room | height [m] |

length [m] |

|---|---|---|

| Day Zone | 2.35 | 2.5 |

| Night Zone | 2.35 | 1.6 |

| Glazing system physical properties | |||||||

| N | Description | x [m] |

k [W/(mK)] |

tauSol [-] |

rhoSol [-] |

tauIR [-] |

absIR [-] |

|---|---|---|---|---|---|---|---|

| 1 | Glass | 0.003 | 1 | 0.6 | 0.075 | 0 | 0.84 |

| 2 | Air | 0.013 | - | - | - | - | |

| 3 | Glass | 0.003 | 1 | 0.075 | 0 | 0.84 | |

| Shading system physical properties | |||

| tauSol [-] |

rhoSol [-] |

tauIR [-] |

absIR [-] |

|---|---|---|---|

| 0.1 | 0.8 | 0 | 0.84 |

The dimensions of the glazing system of the two thermal zones that face towards outside are two parameters that have been defined in the zone components, while the glazing system and shading system physical properties have been defined in the record "Window24".

The thermal zone model also includes the radiant slab component taken from the Modelica Buildings Library. The properties are reported in the following table.

| Radiant slab properties | |

| Pipe distance [m] | 0.1 |

| Interface layer in which pipes are located [-] | 2 |

| Pipe properties | |

| Outer diameter [m] | 0.017 |

| Inner diameter [m] | 0.015 |

| Roughness [m] | 0.000007 |

| Density [kg/m3] | 983 |

| Thermal conductivity [W/(m K)] | 0.4 |

The apartment is occupied from 8 P.M. to 8 A.M. from Monday to Friday by two people, one per thermal zone. The thermal zones are considered unoccupied on Saturday and Sunday.

The heating setpoint is considered 21 [°C] for occupied periods and 16 [°C] for unoccupied periods. The main heat gains come from people, appliances and lighting. For people it corresponds to 60 (W/person) of sensible gains divided equally between convective and radiative contributions and 20 (W) of latent gains. Internal gains for the appliances are 4 (W/m2) and for lighting 1.5 (W/m2) of sensible gains were considred divided equally between convective and radiative contributions. These values are taken from a combination of ASHRAE 90.1 standard and ENI 13200. CO2 generation is 0.0048 L/s per person (Table 5, Persily and De Jonge 2017) and density of CO2 assumed to be 1.8 kg/m^3,making CO2 generation 8.64e-6 kg/s per person.Outside air CO2 concentration is 400 ppm. However, CO2 concentration is not controlled for in the model. Lastly, infilatrations was considered a constant value of 0.5 (vol/h) for each thermal zone.

The climate is assumed to be near Milan, Italy with a latitude and longitude of 45.44,9.27. The climate data comes from the Milano Linate TMY set.

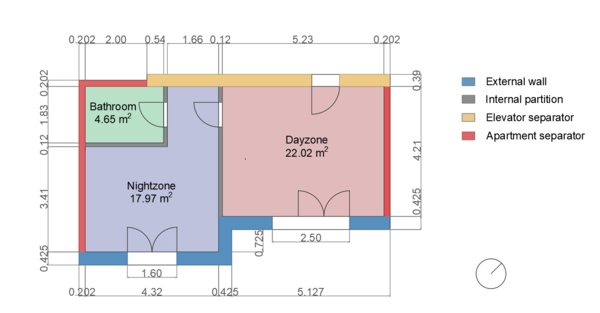

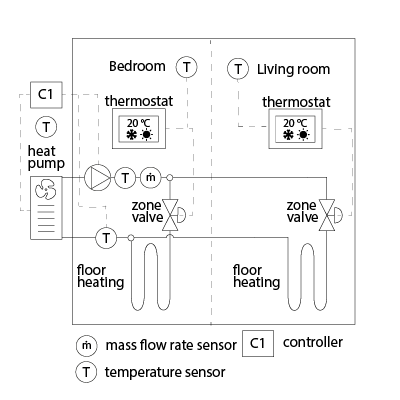

Only heating is considered. The HVAC system is made up of two floor heating circuits, one per thermal zone that can be controlled with a valve. The generation system is an air source heat pump with a nominal heat capacity of 5kW modelled after a Daikin heat pump. Below is reported a schematic view of the HVAC system. Although the baseline controller controls the valves as on-off and the pump with discrete stages, the user can overwrite all control inputs independently with continuous variables, resulting in continuous control.

The heating system circulation pump has the default efficiency of the pump model, which is 49%; at the time of writing. The flow rate for each thermal zone floor heating circuit is 620 [l/h]. The heat pump perfomance map is the default map present in the IDEAS Library heat pump model coming from a Daikin heat pump.

hydronicSystem_oveMDayZ_activate [1] [min=0, max=1]: Activation signal to overwrite input hydronicSystem_oveMDayZ_u where 1 activates, 0 deactivates (default value)

hydronicSystem_oveMDayZ_u [1] [min=0.0, max=1.0]: Signal Day zone valve

hydronicSystem_oveMNigZ_activate [1] [min=0, max=1]: Activation signal to overwrite input hydronicSystem_oveMNigZ_u where 1 activates, 0 deactivates (default value)

hydronicSystem_oveMNigZ_u [1] [min=0.0, max=1.0]: Signal Night zone valve

hydronicSystem_oveMpumCon_activate [1] [min=0, max=1]: Activation signal to overwrite input hydronicSystem_oveMpumCon_u where 1 activates, 0 deactivates (default value)

hydronicSystem_oveMpumCon_u [kg/s] [min=0.0, max=5.0]: Mass flow rate control input to circulation pump for water through floor heating system

hydronicSystem_oveTHea_activate [1] [min=0, max=1]: Activation signal to overwrite input hydronicSystem_oveTHea_u where 1 activates, 0 deactivates (default value)

hydronicSystem_oveTHea_u [K] [min=273.15, max=318.15]: Heat system supply temperature

thermostatDayZon_oveTsetZon_activate [1] [min=0, max=1]: Activation signal to overwrite input thermostatDayZon_oveTsetZon_u where 1 activates, 0 deactivates (default value)

thermostatDayZon_oveTsetZon_u [K] [min=273.15, max=318.15]: Setpoint temperature for thermal zone

thermostatNigZon_oveTsetZon_activate [1] [min=0, max=1]: Activation signal to overwrite input thermostatNigZon_oveTsetZon_u where 1 activates, 0 deactivates (default value)

thermostatNigZon_oveTsetZon_u [K] [min=273.15, max=318.15]: Setpoint temperature for thermal zone

dayZon_reaCO2RooAir_y [ppm] [min=None, max=None]: Zone air CO2 concentration

dayZon_reaMFloHea_y [kg/s] [min=None, max=None]: Zone water mass flow rate floor heating

dayZon_reaPLig_y [W] [min=None, max=None]: Lighting power submeter

dayZon_reaPPlu_y [W] [min=None, max=None]: Plug load power submeter

dayZon_reaPowFlooHea_y [W] [min=None, max=None]: Floor heating power

dayZon_reaPowQint_y [W] [min=None, max=None]: Internal heat gains

dayZon_reaTRooAir_y [K] [min=None, max=None]: Zone air temperature

dayZon_reaTavgFloHea_y [K] [min=None, max=None]: Zone average floor temperature

dayZon_reaTretFloHea_y [K] [min=None, max=None]: Zone return water temperature floor heating

dayZon_reaTsupFloHea_y [K] [min=None, max=None]: Zone supply water temperature floor heating

hydronicSystem_reaCOPhp_y [1] [min=None, max=None]: air source heat pump COP

hydronicSystem_reaPPum_y [W] [min=None, max=None]: Pump electrical power

hydronicSystem_reaPeleHeaPum_y [W] [min=None, max=None]: Electric consumption of the heat pump

hydronicSystem_reaTretFloHea_y [K] [min=None, max=None]: Heat pump return water temperature floor heating

nigZon_reaCO2RooAir_y [ppm] [min=None, max=None]: Zone air CO2 concentration

nigZon_reaMFloHea_y [kg/s] [min=None, max=None]: Zone water mass flow rate floor heating

nigZon_reaPLig_y [W] [min=None, max=None]: Lighting power submeter

nigZon_reaPPlu_y [W] [min=None, max=None]: Plug load power submeter

nigZon_reaPowFlooHea_y [W] [min=None, max=None]: Floor heating power

nigZon_reaPowQint_y [W] [min=None, max=None]: Internal heat gains

nigZon_reaTRooAir_y [K] [min=None, max=None]: Zone air temperature

nigZon_reaTavgFloHea_y [K] [min=None, max=None]: Zone average floor temperature

nigZon_reaTretFloHea_y [K] [min=None, max=None]: Zone return water temperature floor heating

nigZon_reaTsupFloHea_y [K] [min=None, max=None]: Zone supply water temperature floor heating

weatherStation_reaWeaCeiHei_y [m] [min=None, max=None]: Cloud cover ceiling height measurement

weatherStation_reaWeaCloTim_y [s] [min=None, max=None]: Day number with units of seconds

weatherStation_reaWeaHDifHor_y [W/m2] [min=None, max=None]: Horizontal diffuse solar radiation measurement

weatherStation_reaWeaHDirNor_y [W/m2] [min=None, max=None]: Direct normal radiation measurement

weatherStation_reaWeaHGloHor_y [W/m2] [min=None, max=None]: Global horizontal solar irradiation measurement

weatherStation_reaWeaHHorIR_y [W/m2] [min=None, max=None]: Horizontal infrared irradiation measurement

weatherStation_reaWeaLat_y [rad] [min=None, max=None]: Latitude of the location

weatherStation_reaWeaLon_y [rad] [min=None, max=None]: Longitude of the location

weatherStation_reaWeaNOpa_y [1] [min=None, max=None]: Opaque sky cover measurement

weatherStation_reaWeaNTot_y [1] [min=None, max=None]: Sky cover measurement

weatherStation_reaWeaPAtm_y [Pa] [min=None, max=None]: Atmospheric pressure measurement

weatherStation_reaWeaRelHum_y [1] [min=None, max=None]: Outside relative humidity measurement

weatherStation_reaWeaSolAlt_y [rad] [min=None, max=None]: Solar altitude angle measurement

weatherStation_reaWeaSolDec_y [rad] [min=None, max=None]: Solar declination angle measurement

weatherStation_reaWeaSolHouAng_y [rad] [min=None, max=None]: Solar hour angle measurement

weatherStation_reaWeaSolTim_y [s] [min=None, max=None]: Solar time

weatherStation_reaWeaSolZen_y [rad] [min=None, max=None]: Solar zenith angle measurement

weatherStation_reaWeaTBlaSky_y [K] [min=None, max=None]: Black-body sky temperature measurement

weatherStation_reaWeaTDewPoi_y [K] [min=None, max=None]: Dew point temperature measurement

weatherStation_reaWeaTDryBul_y [K] [min=None, max=None]: Outside drybulb temperature measurement

weatherStation_reaWeaTWetBul_y [K] [min=None, max=None]: Wet bulb temperature measurement

weatherStation_reaWeaWinDir_y [rad] [min=None, max=None]: Wind direction measurement

weatherStation_reaWeaWinSpe_y [m/s] [min=None, max=None]: Wind speed measurement

EmissionsBiomassPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh thermal from biomass

EmissionsDistrictHeatingPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh thermal district heating

EmissionsElectricPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh of electricity

EmissionsGasPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh thermal from gas

EmissionsSolarThermalPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh thermal from solar irradiation

HDifHor [W/m2]: Horizontal diffuse solar radiation

HDirNor [W/m2]: Direct normal radiation

HGloHor [W/m2]: Horizontal global radiation

InternalGainsCon[Day] [W]: Convective internal gains of zone

InternalGainsCon[Night] [W]: Convective internal gains of zone

InternalGainsLat[Day] [W]: Latent internal gains of zone

InternalGainsLat[Night] [W]: Latent internal gains of zone

InternalGainsRad[Day] [W]: Radiative internal gains of zone

InternalGainsRad[Night] [W]: Radiative internal gains of zone

LowerSetp[Day] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[Night] [K]: Lower temperature set point for thermal comfort of zone

Occupancy[Day] [number of people]: Number of occupants of zone

Occupancy[Night] [number of people]: Number of occupants of zone

PriceBiomassPower [($/Euro)/kWh]: Price to produce 1 kWh thermal from biomass

PriceDistrictHeatingPower [($/Euro)/kWh]: Price of 1 kWh thermal from district heating

PriceElectricPowerConstant [($/Euro)/kWh]: Completely constant electricity price

PriceElectricPowerDynamic [($/Euro)/kWh]: Electricity price for a day/night tariff

PriceElectricPowerHighlyDynamic [($/Euro)/kWh]: Spot electricity price

PriceGasPower [($/Euro)/kWh]: Price to produce 1 kWh thermal from gas

PriceSolarThermalPower [($/Euro)/kWh]: Price to produce 1 kWh thermal from solar irradiation

TBlaSky [K]: Black Sky temperature

TDewPoi [K]: Dew point temperature

TDryBul [K]: Dry bulb temperature at ground level

TWetBul [K]: Wet bulb temperature

UpperCO2[Day] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[Night] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperSetp[Day] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[Night] [K]: Upper temperature set point for thermal comfort of zone

ceiHei [m]: Ceiling height

cloTim [s]: One-based day number in seconds

lat [rad]: Latitude of the location

lon [rad]: Longitude of the location

nOpa [1]: Opaque sky cover [0, 1]

nTot [1]: Total sky Cover [0, 1]

pAtm [Pa]: Atmospheric pressure

relHum [1]: Relative Humidity

solAlt [rad]: Altitude angel

solDec [rad]: Declination angle

solHouAng [rad]: Solar hour angle.

solTim [s]: Solar time

solZen [rad]: Zenith angle

winDir [rad]: Wind direction

winSpe [m/s]: Wind speed

Artificial lighting is provided by LED lights in the thermal zones.

There are no shades on the building.

There is no energy generation or storage on the site.

A moist air model is used, but condensation is not modeled in the HVAC and humidity is not monitored.

The pump is an ideal constant head pump and provided each floor heating circuit with exactly 620 [l/h] if the circuit valve is open.

A constant infiltration flowrate is assumed to be 0.5 ACH.

No further assumptions are needed.

The Peak Heat Day (specifier for /scenario API is 'peak_heat_day') period is:

The Typical Heat Day (specifier for /scenario API is 'typical_heat_day') period is:

The Constant Electricity Price (specifier for /scenario API is 'constant') profile is:

The Dynamic Electricity Price (specifier for /scenario API is 'dynamic') profile is:

The Highly Dynamic Electricity Price (specifier for /scenario API is 'highly_dynamic') profile is:

The Electricity Emissions Factor profile is:

Options for /scenario API are 'low', 'medium', or 'high'.

Empty or None will lead to deterministic forecasts.

See the BOPTEST design documentation for more information.

Options for /scenario API are 'low', 'medium', or 'high'.

Empty or None will lead to deterministic forecasts.

See the BOPTEST design documentation for more information.