The multi zone office complex air emulator model emulating a large office building with multi-zone VAV systems, chilled water systems, and hot water systems. In the emulator, the Spawn-of-EnergyPlus (Spawn) supports the cosimulation of EnergyPlus and Modelica. EnergyPlus (V9.6) calculates the building’s thermal loads with the boundary conditions. Modelica is responsible for the airflow calculation (e.g., building infiltration) and HVAC system and controls. The geometry of the large offcie building is shown in the figure below.

The layout is representative of the large commercial office building stock and is consistent with the building prototypes. The test case building is located in Chicago, IL and based on the DOE Reference Large Office Building Model (Constructed In or After 1980). The original model has 12 floors with a basement. For simplicity, the middle 10 floors are modeled as a single representative floor using floor multiplier ( i.e., mass flow rate multiplier in Modelica), resulting in three modeled floors (ground, middle, and top), each served by a dedicated AHU, representing 460,233 ft2 (42,757 m2) of total conditioned floor area. The ground floor is assumed to be adiabatic with the basement. EnergyPlus (V9.6) calculates the building’s thermal loads. The detailed input file is wholebuilding96_spawn.idf, containing building geometry, constructions, occupancy and internal schedules, internal mass, etc.

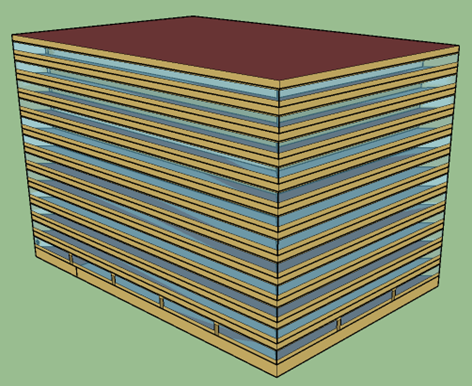

The represented floor has five zones, with four perimeter zones and one core zone. Each perimeter zone has a window-to-wall ratio of about 0.38. The height of each zone is 2.74 m and the areas are as follows:

The geometry of the floor is shown as the following figure:

Opaque constructions: Mass walls; built-up flat roof (insulation above deck); slab-on-grade floor.

Windows: Window-to-wall ratio = 38.0%, equal distribution of windows.

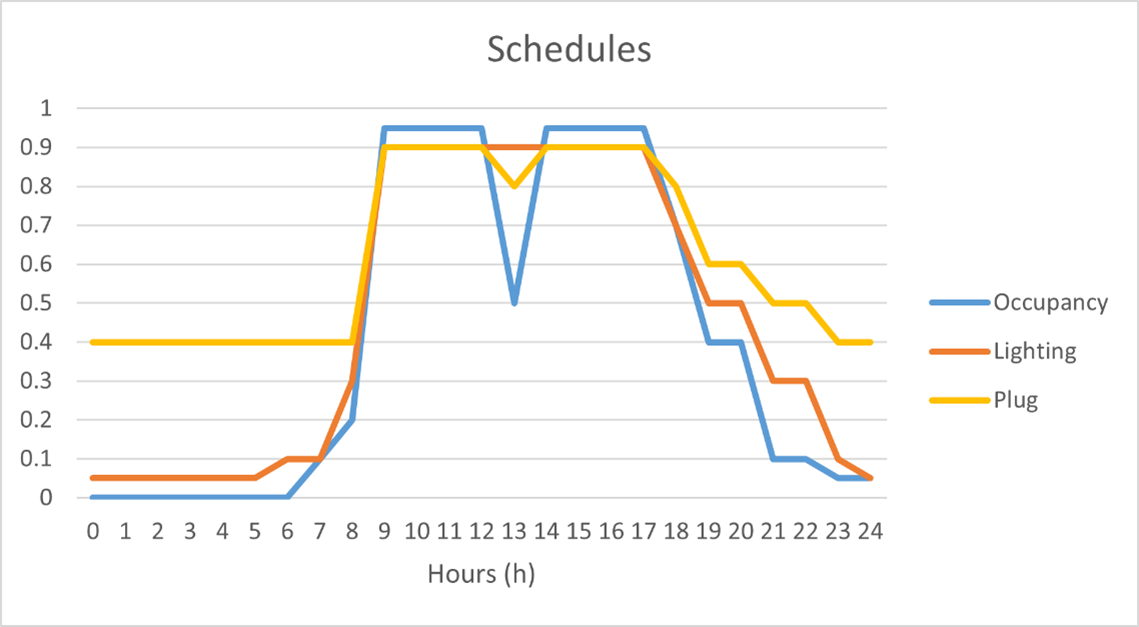

The design occupancy density is 0.05 people/m2. The people internal gain is calculated based on the activity level of 120 W. The number of occupants present in each zone at any time coincides with the internal gain schedule. The occupied time for the HVAC system is between 6:00 and 22:00 each weekday and 6:00 and 18:00 on Saturday. The unoccupied time is outside of this period.

The design internal gains include lighting, plug loads, and people. The lighting load is with a radiant-convective-visible split of 70%-10%-20%. The plug load is with a radiant-convective-latent split of 50%-50%-0%. The people sensible load is with a radiant-convective split of 30%-70%. The occupancy and the internal gains are activated according to the schedule in the figure below.

The power densities of the internal gains are listed in the following table.

| Internal Gains | Power Density [W/m2] |

|---|---|

| Lighting | 16.14 |

| Plug | 10.76 |

The weather data is from TMY3 for Chicago O'Hare International Airport.

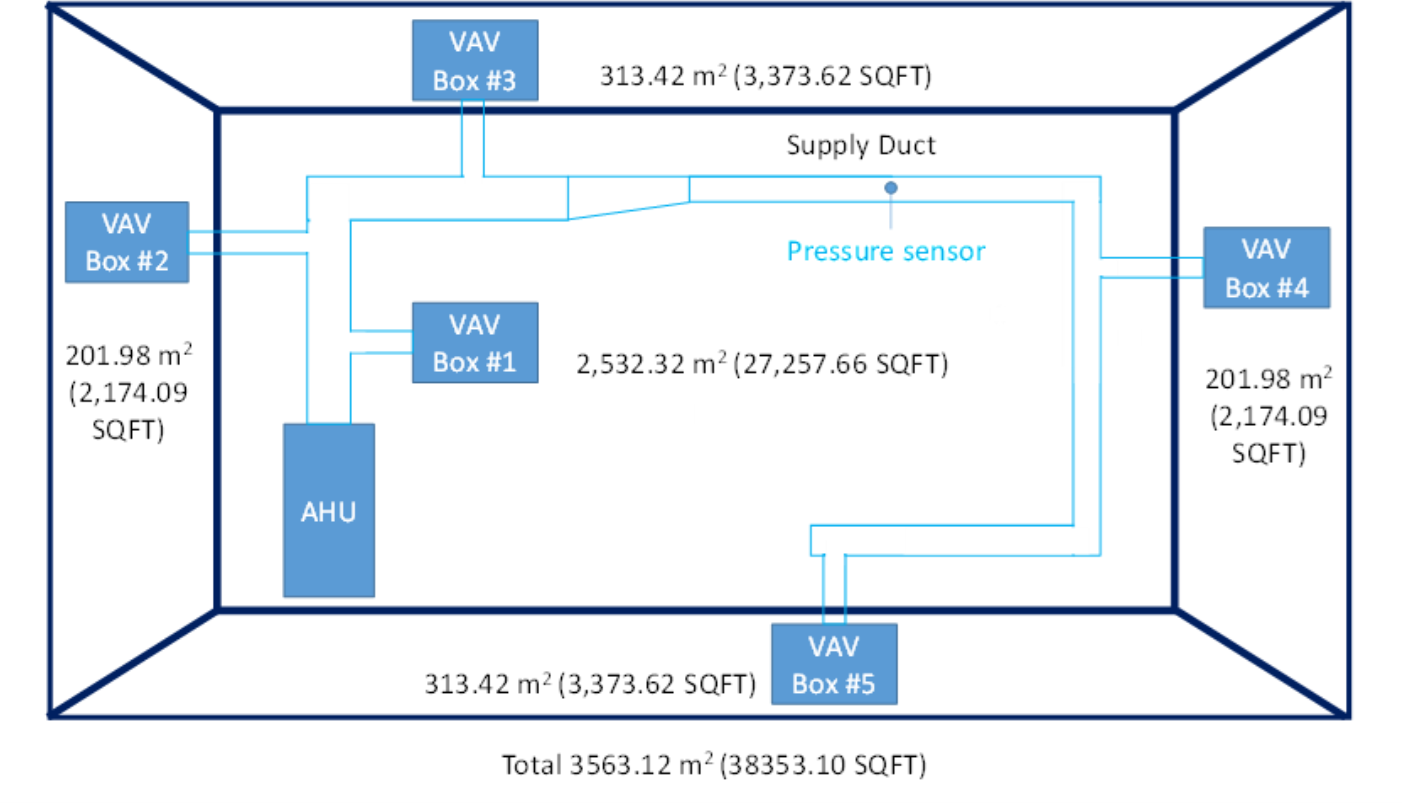

The HVAC system of the test case can be categorized into the air-side systems (i.e., variable air volume (VAV) systems) and water-side systems (i.e., a chilled water systems and a hot water system).

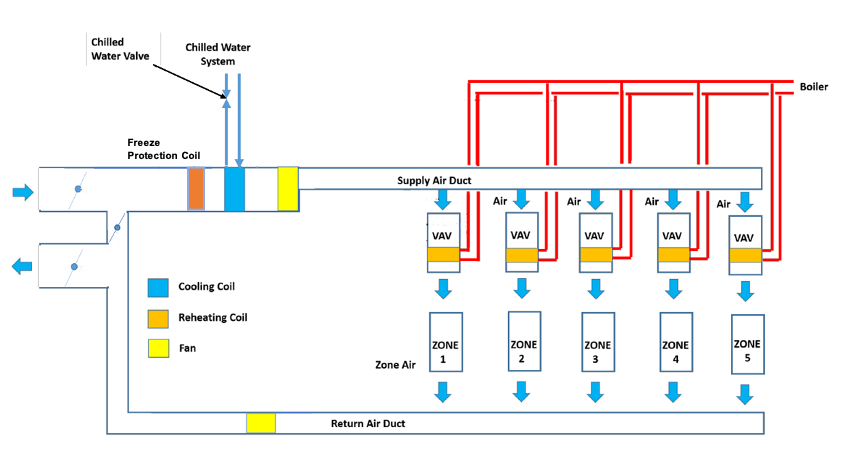

The air-side systems are VAV systems with terminal reheat. Each floor is served by a dedicated AHU and each zone of the test case is served by a dedicated VAV box. The following figure depicts how the VAVs, AHU, and zones are connected on each floor in general. Each AHU has a supply and return fan. A mixing box carries out the economizer function of providing cooling and ventilation. The heating is provided by the water-based reheat coils in the VAV terminals, while an electric resistance freeze protection coil is located in the AHU.

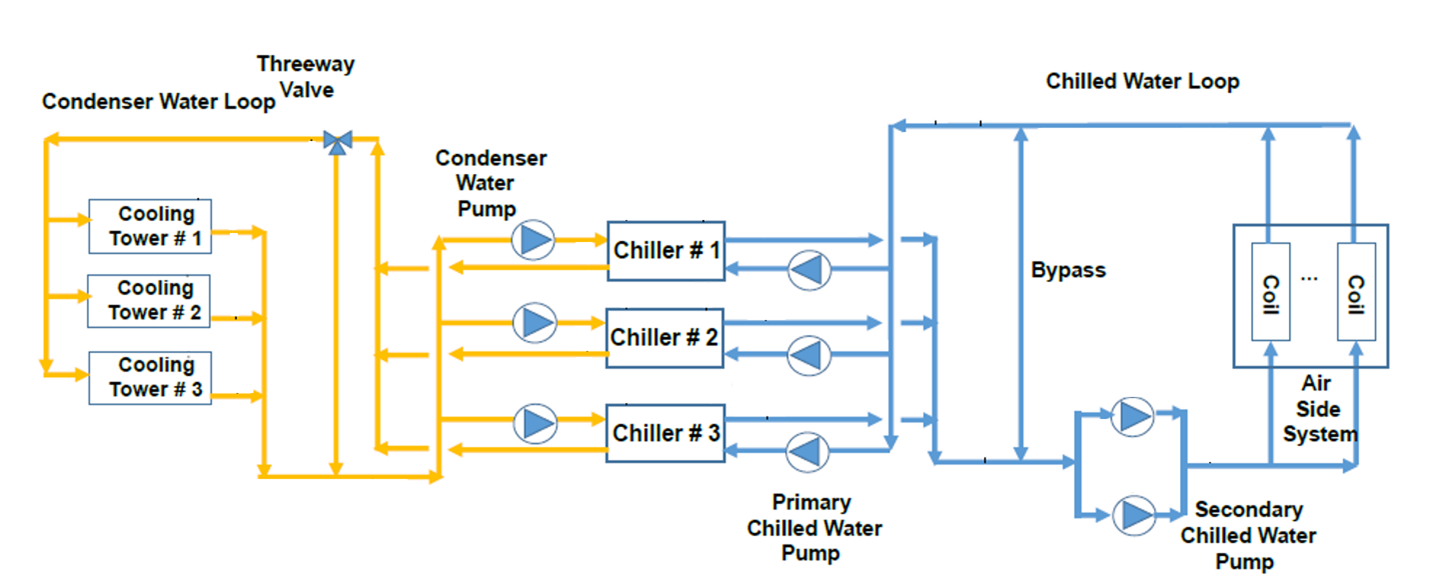

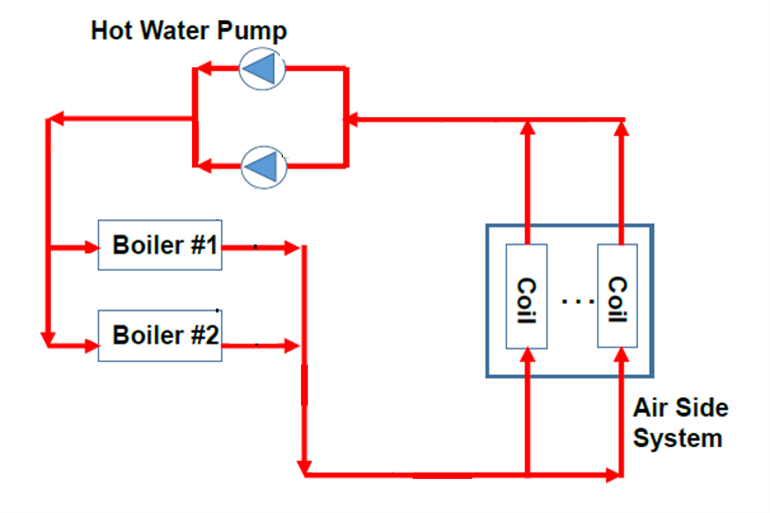

The water-side systems of the test case include one chilled water system and one hot water system. The chilled water systems are composed of three chillers, three cooling towers, a primary chilled water loop with three constant speed pumps, a secondary chilled water loop with two variable speed pumps, and a condenser water loop with three constant speed pumps. The hot water system consists of two gas boilers and two variable speed pumps. The figure below shows the schematics of the chilled water and hot water systems.

The HVAC sizing in Modelica is determined by the annual simulation results of EnergyPlus. The pressure loop related sizing parameters are estimated using a common HVAC design procedure. The following tables list all the sizing parameters in detail. See later sections for specific control details.

| VAV terminal with Reheat Coil | Design Air Mass Flow Rate [kg/s] | Minimum Cooling Air Mass Flow Rate Setpoint [kg/s] | Heating Air Mass Flow Rate Setpoint [kg/s] | Minimum Damper Position [0-1] | Design Reheat Coil Water Mass Flow Rate [kg/s] |

|---|---|---|---|---|---|

| Bot Floor Core Zone VAV | 49.1 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 3.88 |

| Mid Floor Core Zone VAV | 491.4 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 38.8 |

| Top Floor Core Zone VAV | 49.1 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 3.88 |

| Bot Floor South Zone VAV | 10.1 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.8 |

| Bot Floor East Zone VAV | 6.7 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.53 |

| Bot Floor North Zone VAV | 8.6 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.68 |

| Bot Floor West Zone VAV | 7.8 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.62 |

| Mid Floor South Zone VAV | 101.2 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 8 |

| Mid Floor East Zone VAV | 67 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 5.3 |

| Mid Floor North Zone VAV | 85.5 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 6.8 |

| Mid Floor West Zone VAV | 77.9 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 6.2 |

| Top Floor South Zone VAV | 10.1 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.8 |

| Top Floor East Zone VAV | 6.7 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.53 |

| Top Floor North Zone VAV | 8.6 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.68 |

| Top Floor West Zone VAV | 7.8 | 0.3 of design air mass flow rate | 0.3 of design air mass flow rate | 0.3 | 0.62 |

| AHU Cooling Coils | Design Coil Capacity [W] | Design Water Mass Flow Rate [kg/s] | Design Air Mass Flow Rate [m3/s] |

|---|---|---|---|

| Bot Floor Cooling Coil | 750,000 | 26 | 70 |

| Mid Floor Cooling Coil | 7,500,000 | 260 | 700 |

| Top Floor Cooling Coil | 1,000,000 | 30 | 70 |

| AHU Freeze Protection Coils | Design Coil Capacity [W] |

|---|---|

| Bot Floor Freeze Coil | 1,650,000 |

| Mid Floor Freeze Coil | 16,500,000 |

| Top Floor Freeze Coil | 1,650,000 |

| Fans | Type | Design Size Supply Fan Mass Flow Rate [kg/s] | Design Size Supply Fan Pressure Head [Pa] | Total Efficiency | Design Power Consumption [W] |

|---|---|---|---|---|---|

| Bot Floor Supply Fan | Variable speed | 70 | 1000 | 0.72 | 97,222 |

| Mid Floor Supply Fan | Variable speed | 700 | 1000 | 0.72 | 972,222 |

| Top Floor Supply Fan | Variable speed | 70 | 1000 | 0.72 | 97,222 |

| Bot Floor Return Fan | Variable speed | 70 | 300 | 0.72 | 29,167 |

| Mid Floor Return Fan | Variable speed | 700 | 300 | 0.72 | 291,667 |

| Top Floor Return Fan | Variable speed | 70 | 300 | 0.72 | 29,167 |

| Pumps | Type | Design Mass Flow Rate [kg/s] | Design Size Supply Pump Pressure Head [Pa] | Total Efficiency | Design Power Consumption [W] |

|---|---|---|---|---|---|

| CHW Primary Pumps 1-3 | Constant speed | 105 | 211,000 | 0.87 | 25,000 |

| CHW Secondary Pumps 1-2 | Variable speed | 155 | 478,000 | 0.88 | 90,000 |

| CW Pumps 1-3 | Variable speed | 123 | 571,100 | 0.87 | 81,000 |

| HW Pumps 1-2 | Variable speed | 39 | 478,250 | 0.86 | 22,900 |

| Chillers | Design Chilled Water Mass Flow Rate [kg/s] | Design Condenser Water Mass Flow Rate [kg/s] | Design Capacity [W] |

|---|---|---|---|

| Chillers 1-3 | 105 | 123 | 2,600,000 |

| Boilers | Design Hot Water Mass Flow Rate [kg/s] | Design Capacity [W] |

|---|---|---|

| Boiler 1-2 | 39 | 3,300,000 |

| Cooling Towers | Design Water Mass Flow Rate [kg/s] | Fan Power at Design Air Flow Rate [W] |

|---|---|---|

| Cooling Towers 1-2 | 123 | 43,000 |

Zone air temperature setpoints and equipment enable/disable are determined by a schedule-based supervisory control scheme that defines a set of operating modes. The table below shows the zone air temperature setpoints, fan, and pump enable/disable.

| Name | Condition | TZonHeaSet [oC] | TZonCooSet [oC] | Fan | Pump | TSupSet [oC] | Economizer | Min OA Flow |

|---|---|---|---|---|---|---|---|---|

| Occupied | In occupied period. | 20 | 24 | Enabled | Enabled | 12.8 | Enabled | Ventilation |

| Unoccupied off | In unoccupied period, all TZon within setback deadband. | 15.6 | 26.7 | Disabled | Enabled (With the lowest flow rate) | 12.8 | Disabled | Zero |

| Unoccupied, night setback | In unoccupied period, triggered by minimum TZon below unoccupied TZonHeaSet. Minimum state time is 60 min. | 15.6 | 26.7 | Enabled | Enabled | 12.8 | Disabled | Zero |

| Unoccupied, night setup | In unoccupied period, triggered by maximum TZon above unoccupied TZonCooSet. Minimum state time is 60 min. | 15.6 | 26.7 | Enabled | Enabled | 12.8 | Disabled | Zero |

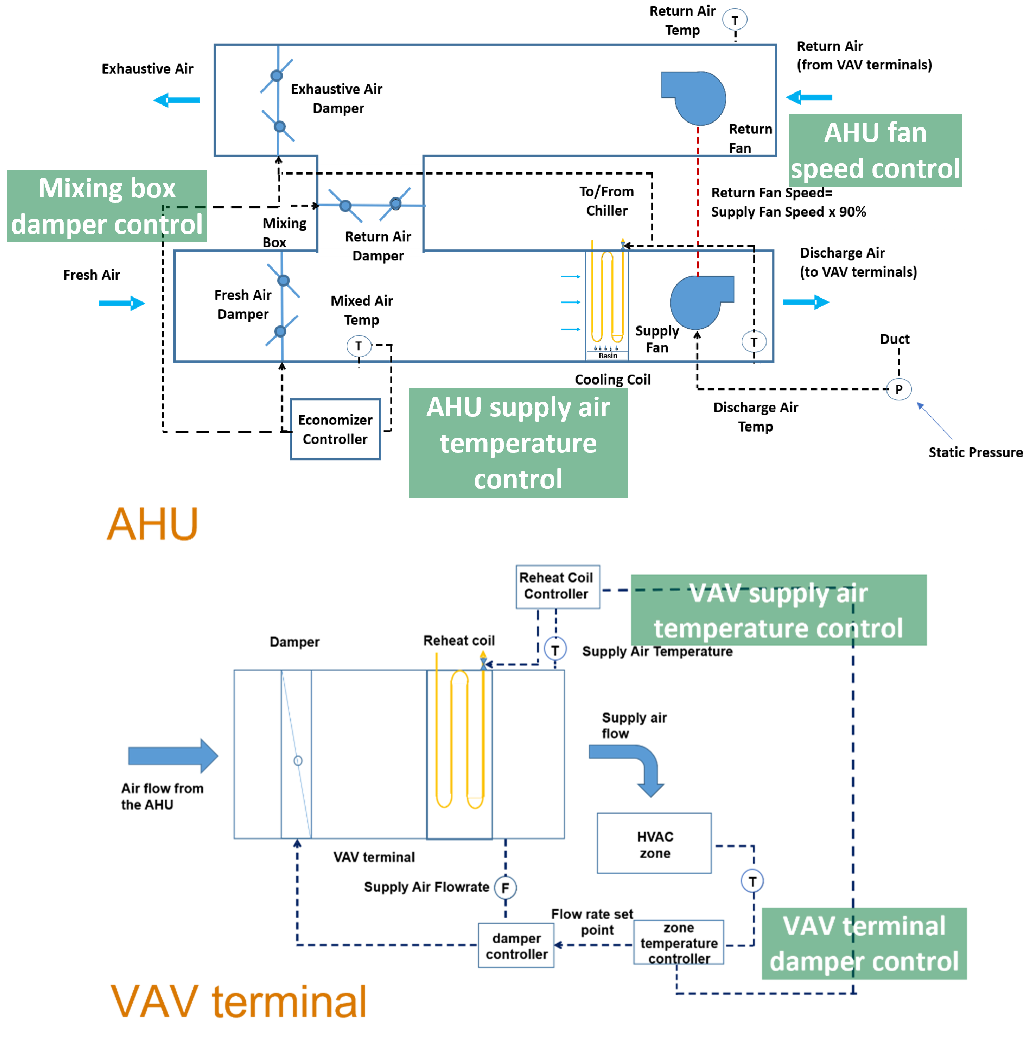

Once the operating mode is determined, a number of low-level, local-loop controllers are used to maintain the desired setpoints using the available actuators. The primary local-loop controllers are specified in the HVAC system control section.

VAV reheat control

The VAV reheat is controlled based on the "single maximum VAV reheat control logic".

VAV air flow rate control

VAV damper position is controlled by a PI controller to maintain the air flow rate at setpoint. It takes the zone air flow rate measurements and setpoints as inputs. It takes the VAV damper position as the output.

VAV supply air temperature control

Heating coil valve position is controlled by a PI controller to maintain the supply air temperature at setpoint. It takes the supply air temperature measurements and setpoint as inputs. It takes the heating coil valve position as the output.

AHU duct static pressure control

The supply fan speed is regulated by a PI controller to maintain the duct static pressure at its setpoint of 400 Pa (or 1.61 in. w.c.). It takes the static pressure measurements and setpoints as inputs. It takes the supply fan speed as the output. The AHU return fan speed is set as a constant ratio (0.9) of the supply fan speed.

During unoccupied hours, the night-cycle control is activated. If any zone air temperature falls outside the setback temperature bounds, the fans are switched on to bring the zone air temperature back within the allowable range.

AHU supply air temperature control

Cooling coil valve position is controlled by a PI controller to maintain the AHU supply air temperature at setpoint. It takes the supply air temperature measurements and setpoints as inputs. It takes the cooling coil valve position as the output.

Mixing box damper and economizer control

The minimum outdoor air damper position is 0.3 in order to provide ventilation. On top of that, an economizer control based on the fixed dry-bulb outdoor air temperature-based is adopted. The economizer higher temperature limit is set as 15.58 oC (60 oF), while the lower temperature limit is set as 0 oC (32 oF). Under economizer control, the outdoor air damper position is regulated by a PI controller to maintain the mixed air temperature at its setpoint, with a minimum damper position of 0.3. The controller uses the mixed air temperature, outdoor air temperature, and the mixed air temperature setpoint as inputs. Its output is the commanded outdoor air damper position. The return air damper is interlocked with the outdoor air damper as the inverse, while the exhaust air damper is interlocked with the outdoor air damper as sharing the same opening position. Note, however, that overwriting any of these damper positions bypasses the interlocks, thus they should be controlled as a group.

AHU freeze protection coil control

The freeze protection coil is turned on if the mixed air temperature is measured to be below the freeze protection temperature set point (3.33 oC) and the supply airflow rate is at or above 10% of the design value. Once activated, the coil remains on for at least 5 minutes and until the mixed air temperature raises above the set point. Overwriting the freeze coil control signal will bypass the minimum on-time, but will not bypass the airflow switch as a safety.

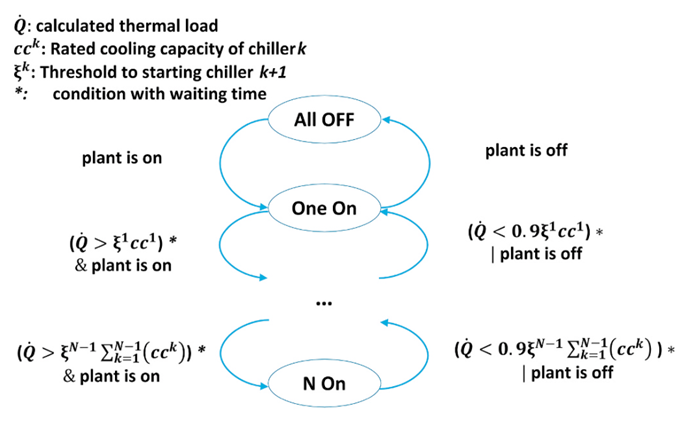

Chiller plant staging control

The number of operating chillers is determined via a state machine based on the thermal load (Q, kW), rated chiller cooling capacity of chiller k (cck, kW), threshold to start chiller k+1 (ξk = 0.9), and waiting time (15 min). The maximum operating chiller number is N, which is equal to 3.

The stage control logic is shown as the following figure.

Chilled water supply temperature control

The model takes as an input the set point for the leaving chilled water temperature, which is met if the chiller has sufficient capacity. Thus, the model has a built-in, ideal temperature control.

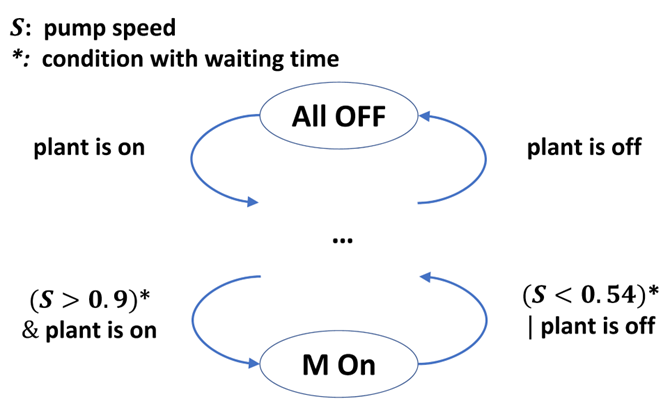

Secondary chilled water pump staging control

The number of secondary chilled water pump is determined via a state machine based on the pump speed (S, rpm) and waiting time (30 min). The maximum operating pump number is M, which is equal to 2.

The stage control logic is shown as the following figure.

Secondary chilled water loop static pressure control

Secondary chilled water pump speed is controlled by a PI controller to maintain the static pressure of the secondary chilled water loop at setpoint. It takes the chilled water loop static pressure measurements and setpoints as inputs. It takes the pump speed as the output. The operating secondary chilled water pumps share the same speed.

Cooling tower supply water temperature control

Cooling tower fan speed is controlled by a PI controller to maintain the cooling tower supply water temperature at setpoint. It takes the cooling tower supply water temperature measurements and setpoints as inputs. It takes the cooling tower fan speed as the output. All the operating cooling towers share the same fan speed.

Minimum condenser supply water temperature control

Three-way valve position is controlled by a PI controller to maintain the temperature of the condenser water leaving the condenser water loop to be larger than 15.56 ℃. It takes the condenser supply water temperature measurements and setpoints as inputs. It takes the three-way valve position as the output.

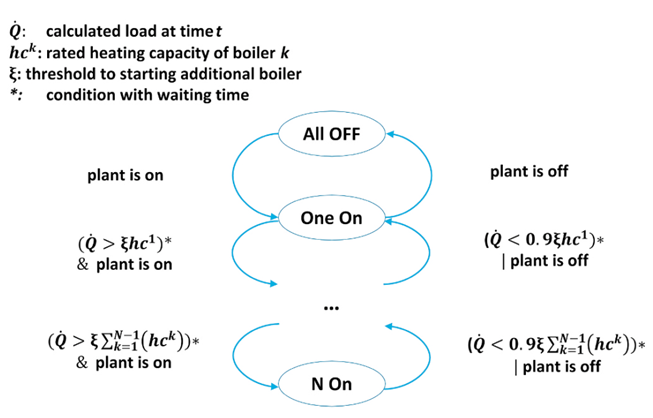

Boiler staging control

The number of operating boilers is determined via a state machine based on the thermal load(Q, kW), rated heating capacity of boiler k (hck, kW), threshold to start boiler k+1 (ξk = 0.9), and waiting time (30 min). The maximum operating boiler number is N, which is equal to 2.

The stage control logic is shown as the following figure.

Boiler water temperature control

Boiler heating power is controlled by a PI controller to maintain the temperature of the hot water leaving each boiler to be 80 ℃. It takes the hot water measurements and set points as inputs. It takes the heating power as the output.

Boiler hot water loop static pressure control

Boiler pump speed is controlled by a PI controller to maintain the static pressure of the boiler water loop at setpoint. It takes the heat water loop static pressure measurements and setpoints as inputs. It takes the pump speed as the output. All the boiler pumps share the same speed.

floor1_TSupAirSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_TSupAirSet_u where 1 activates, 0 deactivates (default value)

floor1_TSupAirSet_u [K] [min=285.15, max=313.15]: Supply air temperature setpoint for AHU

floor1_dpSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_dpSet_u where 1 activates, 0 deactivates (default value)

floor1_dpSet_u [Pa] [min=50, max=410]: Supply duct pressure setpoint for AHU

floor1_duaFanAirHanUni_cooCoi_yCoo_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_cooCoi_yCoo_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_cooCoi_yCoo_u [1] [min=0, max=1]: Cooling coil valve control signal for AHU

floor1_duaFanAirHanUni_frePro_oveFrePro_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_frePro_oveFrePro_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_frePro_oveFrePro_u [1] [min=0, max=1]: Control signal for freeze protection coil

floor1_duaFanAirHanUni_mixingBox_mixBox_yEA_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_mixingBox_mixBox_yEA_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_mixingBox_mixBox_yEA_u [1] [min=0, max=1]: Exhaust air damper position setpoint for AHU

floor1_duaFanAirHanUni_mixingBox_mixBox_yOA_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_mixingBox_mixBox_yOA_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_mixingBox_mixBox_yOA_u [1] [min=0, max=1]: Outside air damper position setpoint for AHU

floor1_duaFanAirHanUni_mixingBox_mixBox_yRet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_mixingBox_mixBox_yRet_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_mixingBox_mixBox_yRet_u [1] [min=0, max=1]: Return air damper position setpoint for AHU

floor1_duaFanAirHanUni_oveSpeRetFan_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_oveSpeRetFan_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_oveSpeRetFan_u [1] [min=0, max=1]: AHU return fan speed control signal

floor1_duaFanAirHanUni_supFan_oveSpeSupFan_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_duaFanAirHanUni_supFan_oveSpeSupFan_u where 1 activates, 0 deactivates (default value)

floor1_duaFanAirHanUni_supFan_oveSpeSupFan_u [1] [min=0, max=1]: AHU supply fan speed control signal

floor1_fivZonVAV_vAV1_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV1_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV1_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone cor

floor1_fivZonVAV_vAV1_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV1_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV1_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone cor

floor1_fivZonVAV_vAV2_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV2_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV2_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone sou

floor1_fivZonVAV_vAV2_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV2_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV2_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone sou

floor1_fivZonVAV_vAV3_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV3_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV3_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone eas

floor1_fivZonVAV_vAV3_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV3_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV3_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone eas

floor1_fivZonVAV_vAV4_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV4_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV4_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone nor

floor1_fivZonVAV_vAV4_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV4_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV4_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone nor

floor1_fivZonVAV_vAV5_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV5_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV5_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone wes

floor1_fivZonVAV_vAV5_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_fivZonVAV_vAV5_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor1_fivZonVAV_vAV5_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone wes

floor1_oveZonCor_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonCor_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonCor_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone bot_floor_cor

floor1_oveZonCor_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonCor_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonCor_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone bot_floor_cor

floor1_oveZonEas_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonEas_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonEas_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone bot_floor_eas

floor1_oveZonEas_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonEas_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonEas_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone bot_floor_eas

floor1_oveZonNor_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonNor_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonNor_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone bot_floor_nor

floor1_oveZonNor_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonNor_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonNor_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone bot_floor_nor

floor1_oveZonSou_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonSou_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonSou_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone bot_floor_sou

floor1_oveZonSou_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonSou_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonSou_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone bot_floor_sou

floor1_oveZonWes_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonWes_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonWes_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone bot_floor_wes

floor1_oveZonWes_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor1_oveZonWes_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor1_oveZonWes_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone bot_floor_wes

floor2_TSupAirSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_TSupAirSet_u where 1 activates, 0 deactivates (default value)

floor2_TSupAirSet_u [K] [min=285.15, max=313.15]: Supply air temperature setpoint for AHU

floor2_dpSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_dpSet_u where 1 activates, 0 deactivates (default value)

floor2_dpSet_u [Pa] [min=50, max=410]: Supply duct pressure setpoint for AHU

floor2_duaFanAirHanUni_cooCoi_yCoo_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_cooCoi_yCoo_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_cooCoi_yCoo_u [1] [min=0, max=1]: Cooling coil valve control signal for AHU

floor2_duaFanAirHanUni_frePro_oveFrePro_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_frePro_oveFrePro_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_frePro_oveFrePro_u [1] [min=0, max=1]: Control signal for freeze protection coil

floor2_duaFanAirHanUni_mixingBox_mixBox_yEA_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_mixingBox_mixBox_yEA_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_mixingBox_mixBox_yEA_u [1] [min=0, max=1]: Exhaust air damper position setpoint for AHU

floor2_duaFanAirHanUni_mixingBox_mixBox_yOA_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_mixingBox_mixBox_yOA_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_mixingBox_mixBox_yOA_u [1] [min=0, max=1]: Outside air damper position setpoint for AHU

floor2_duaFanAirHanUni_mixingBox_mixBox_yRet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_mixingBox_mixBox_yRet_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_mixingBox_mixBox_yRet_u [1] [min=0, max=1]: Return air damper position setpoint for AHU

floor2_duaFanAirHanUni_oveSpeRetFan_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_oveSpeRetFan_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_oveSpeRetFan_u [1] [min=0, max=1]: AHU return fan speed control signal

floor2_duaFanAirHanUni_supFan_oveSpeSupFan_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_duaFanAirHanUni_supFan_oveSpeSupFan_u where 1 activates, 0 deactivates (default value)

floor2_duaFanAirHanUni_supFan_oveSpeSupFan_u [1] [min=0, max=1]: AHU supply fan speed control signal

floor2_fivZonVAV_vAV1_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV1_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV1_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone cor

floor2_fivZonVAV_vAV1_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV1_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV1_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone cor

floor2_fivZonVAV_vAV2_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV2_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV2_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone sou

floor2_fivZonVAV_vAV2_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV2_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV2_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone sou

floor2_fivZonVAV_vAV3_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV3_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV3_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone eas

floor2_fivZonVAV_vAV3_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV3_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV3_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone eas

floor2_fivZonVAV_vAV4_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV4_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV4_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone nor

floor2_fivZonVAV_vAV4_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV4_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV4_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone nor

floor2_fivZonVAV_vAV5_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV5_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV5_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone wes

floor2_fivZonVAV_vAV5_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_fivZonVAV_vAV5_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor2_fivZonVAV_vAV5_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone wes

floor2_oveZonCor_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonCor_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonCor_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone mid_floor_cor

floor2_oveZonCor_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonCor_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonCor_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone mid_floor_cor

floor2_oveZonEas_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonEas_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonEas_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone mid_floor_eas

floor2_oveZonEas_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonEas_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonEas_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone mid_floor_eas

floor2_oveZonNor_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonNor_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonNor_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone mid_floor_nor

floor2_oveZonNor_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonNor_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonNor_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone mid_floor_nor

floor2_oveZonSou_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonSou_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonSou_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone mid_floor_sou

floor2_oveZonSou_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonSou_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonSou_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone mid_floor_sou

floor2_oveZonWes_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonWes_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonWes_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone mid_floor_wes

floor2_oveZonWes_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor2_oveZonWes_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor2_oveZonWes_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone mid_floor_wes

floor3_TSupAirSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_TSupAirSet_u where 1 activates, 0 deactivates (default value)

floor3_TSupAirSet_u [K] [min=285.15, max=313.15]: Supply air temperature setpoint for AHU

floor3_dpSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_dpSet_u where 1 activates, 0 deactivates (default value)

floor3_dpSet_u [Pa] [min=50, max=410]: Supply duct pressure setpoint for AHU

floor3_duaFanAirHanUni_cooCoi_yCoo_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_cooCoi_yCoo_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_cooCoi_yCoo_u [1] [min=0, max=1]: Cooling coil valve control signal for AHU

floor3_duaFanAirHanUni_frePro_oveFrePro_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_frePro_oveFrePro_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_frePro_oveFrePro_u [1] [min=0, max=1]: Control signal for freeze protection coil

floor3_duaFanAirHanUni_mixingBox_mixBox_yEA_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_mixingBox_mixBox_yEA_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_mixingBox_mixBox_yEA_u [1] [min=0, max=1]: Exhaust air damper position setpoint for AHU

floor3_duaFanAirHanUni_mixingBox_mixBox_yOA_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_mixingBox_mixBox_yOA_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_mixingBox_mixBox_yOA_u [1] [min=0, max=1]: Outside air damper position setpoint for AHU

floor3_duaFanAirHanUni_mixingBox_mixBox_yRet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_mixingBox_mixBox_yRet_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_mixingBox_mixBox_yRet_u [1] [min=0, max=1]: Return air damper position setpoint for AHU

floor3_duaFanAirHanUni_oveSpeRetFan_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_oveSpeRetFan_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_oveSpeRetFan_u [1] [min=0, max=1]: AHU return fan speed control signal

floor3_duaFanAirHanUni_supFan_oveSpeSupFan_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_duaFanAirHanUni_supFan_oveSpeSupFan_u where 1 activates, 0 deactivates (default value)

floor3_duaFanAirHanUni_supFan_oveSpeSupFan_u [1] [min=0, max=1]: AHU supply fan speed control signal

floor3_fivZonVAV_vAV1_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV1_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV1_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone cor

floor3_fivZonVAV_vAV1_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV1_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV1_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone cor

floor3_fivZonVAV_vAV2_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV2_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV2_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone sou

floor3_fivZonVAV_vAV2_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV2_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV2_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone sou

floor3_fivZonVAV_vAV3_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV3_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV3_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone eas

floor3_fivZonVAV_vAV3_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV3_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV3_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone eas

floor3_fivZonVAV_vAV4_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV4_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV4_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone nor

floor3_fivZonVAV_vAV4_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV4_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV4_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone nor

floor3_fivZonVAV_vAV5_oveZonLoc_yDam_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV5_oveZonLoc_yDam_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV5_oveZonLoc_yDam_u [1] [min=0, max=1]: Damper position signal for zone wes

floor3_fivZonVAV_vAV5_oveZonLoc_yReaHea_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_fivZonVAV_vAV5_oveZonLoc_yReaHea_u where 1 activates, 0 deactivates (default value)

floor3_fivZonVAV_vAV5_oveZonLoc_yReaHea_u [1] [min=0, max=1]: Reheat control signal for zone wes

floor3_oveZonCor_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonCor_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonCor_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone top_floor_cor

floor3_oveZonCor_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonCor_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonCor_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone top_floor_cor

floor3_oveZonEas_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonEas_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonEas_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone top_floor_eas

floor3_oveZonEas_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonEas_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonEas_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone top_floor_eas

floor3_oveZonNor_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonNor_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonNor_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone top_floor_nor

floor3_oveZonNor_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonNor_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonNor_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone top_floor_nor

floor3_oveZonSou_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonSou_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonSou_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone top_floor_sou

floor3_oveZonSou_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonSou_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonSou_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone top_floor_sou

floor3_oveZonWes_TZonCooSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonWes_TZonCooSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonWes_TZonCooSet_u [K] [min=285.15, max=313.15]: Zone air temperature cooling setpoint for zone top_floor_wes

floor3_oveZonWes_TZonHeaSet_activate [1] [min=0, max=1]: Activation signal to overwrite input floor3_oveZonWes_TZonHeaSet_u where 1 activates, 0 deactivates (default value)

floor3_oveZonWes_TZonHeaSet_u [K] [min=285.15, max=313.15]: Zone air temperature heating setpoint for zone top_floor_wes

oveChiWatSys_TWSet_activate [1] [min=0, max=1]: Activation signal to overwrite input oveChiWatSys_TWSet_u where 1 activates, 0 deactivates (default value)

oveChiWatSys_TWSet_u [K] [min=278.15, max=288.15]: Chilled/hot water supply setpoint

oveChiWatSys_dpSet_activate [1] [min=0, max=1]: Activation signal to overwrite input oveChiWatSys_dpSet_u where 1 activates, 0 deactivates (default value)

oveChiWatSys_dpSet_u [Pa] [min=0, max=19130000]: Differential pressure setpoint

oveHotWatSys_TWSet_activate [1] [min=0, max=1]: Activation signal to overwrite input oveHotWatSys_TWSet_u where 1 activates, 0 deactivates (default value)

oveHotWatSys_TWSet_u [K] [min=291.15, max=353.15]: Chilled/hot water supply setpoint

oveHotWatSys_dpSet_activate [1] [min=0, max=1]: Activation signal to overwrite input oveHotWatSys_dpSet_u where 1 activates, 0 deactivates (default value)

oveHotWatSys_dpSet_u [Pa] [min=0, max=19130000]: Differential pressure setpoint

floor1_reaAHU_CO2_AHUFre_y [ppm] [min=None, max=None]: Fresh air CO2 measurement for AHU

floor1_reaAHU_CO2_AHURet_y [ppm] [min=None, max=None]: Return air CO2 measurement for AHU

floor1_reaAHU_CO2_AHUSup_y [ppm] [min=None, max=None]: Supply air CO2 measurement for AHU

floor1_reaAHU_PFanRet_y [W] [min=None, max=None]: Electrical power measurement of return fan for AHU

floor1_reaAHU_PFanSup_y [W] [min=None, max=None]: Electrical power measurement of supply fan for AHU

floor1_reaAHU_PFreCoi_y [W] [min=None, max=None]: Electrical power measurement of freeze protection coil for AHU

floor1_reaAHU_TCooCoiRet_y [K] [min=None, max=None]: Cooling coil return water temperature measurement for AHU

floor1_reaAHU_TCooCoiSup_y [K] [min=None, max=None]: Cooling coil supply water temperature measurement for AHU

floor1_reaAHU_TFreCoiLea_y [K] [min=None, max=None]: Temperature of air leaving freeze protection coil

floor1_reaAHU_TMix_y [K] [min=None, max=None]: Mixed air temperature measurement for AHU

floor1_reaAHU_TRet_y [K] [min=None, max=None]: Return air temperature measurement for AHU

floor1_reaAHU_TSup_y [K] [min=None, max=None]: Supply air temperature measurement for AHU

floor1_reaAHU_V_flowOA_y [m3/s] [min=None, max=None]: Supply outdoor airflow rate measurement for AHU

floor1_reaAHU_V_flowRet_y [m3/s] [min=None, max=None]: Return air flowrate measurement for AHU

floor1_reaAHU_V_flowSup_y [m3/s] [min=None, max=None]: Supply air flowrate measurement for AHU

floor1_reaAHU_dp_y [Pa] [min=None, max=None]: Static pressure of supply fan for AHU

floor1_reaAHU_occ_y [1] [min=None, max=None]: Occupancy status (1 occupied, 0 unoccupied)

floor1_reaAHU_phiAHURet_y [1] [min=None, max=None]: Return air relative humidity for AHU

floor1_reaAHU_phiAHUSup_y [1] [min=None, max=None]: Supply air relative humidity for AHU

floor1_reaAHU_yCooVal_y [1] [min=None, max=None]: AHU cooling coil valve position measurement

floor1_reaAHU_yOA_y [1] [min=None, max=None]: AHU OA damper position measurement

floor1_reaZonCor_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone bot_floor_cor

floor1_reaZonCor_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone bot_floor_cor

floor1_reaZonCor_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone bot_floor_cor

floor1_reaZonCor_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone bot_floor_cor

floor1_reaZonCor_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone bot_floor_cor

floor1_reaZonCor_yDam_y [1] [min=None, max=None]: Damper position measurement for zone bot_floor_cor

floor1_reaZonCor_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone bot_floor_cor

floor1_reaZonEas_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone bot_floor_eas

floor1_reaZonEas_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone bot_floor_eas

floor1_reaZonEas_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone bot_floor_eas

floor1_reaZonEas_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone bot_floor_eas

floor1_reaZonEas_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone bot_floor_eas

floor1_reaZonEas_yDam_y [1] [min=None, max=None]: Damper position measurement for zone bot_floor_eas

floor1_reaZonEas_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone bot_floor_eas

floor1_reaZonNor_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone bot_floor_nor

floor1_reaZonNor_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone bot_floor_nor

floor1_reaZonNor_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone bot_floor_nor

floor1_reaZonNor_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone bot_floor_nor

floor1_reaZonNor_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone bot_floor_nor

floor1_reaZonNor_yDam_y [1] [min=None, max=None]: Damper position measurement for zone bot_floor_nor

floor1_reaZonNor_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone bot_floor_nor

floor1_reaZonSou_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone bot_floor_sou

floor1_reaZonSou_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone bot_floor_sou

floor1_reaZonSou_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone bot_floor_sou

floor1_reaZonSou_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone bot_floor_sou

floor1_reaZonSou_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone bot_floor_sou

floor1_reaZonSou_yDam_y [1] [min=None, max=None]: Damper position measurement for zone bot_floor_sou

floor1_reaZonSou_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone bot_floor_sou

floor1_reaZonWes_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone bot_floor_wes

floor1_reaZonWes_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone bot_floor_wes

floor1_reaZonWes_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone bot_floor_wes

floor1_reaZonWes_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone bot_floor_wes

floor1_reaZonWes_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone bot_floor_wes

floor1_reaZonWes_yDam_y [1] [min=None, max=None]: Damper position measurement for zone bot_floor_wes

floor1_reaZonWes_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone bot_floor_wes

floor2_reaAHU_CO2_AHUFre_y [ppm] [min=None, max=None]: Fresh air CO2 measurement for AHU

floor2_reaAHU_CO2_AHURet_y [ppm] [min=None, max=None]: Return air CO2 measurement for AHU

floor2_reaAHU_CO2_AHUSup_y [ppm] [min=None, max=None]: Supply air CO2 measurement for AHU

floor2_reaAHU_PFanRet_y [W] [min=None, max=None]: Electrical power measurement of return fan for AHU

floor2_reaAHU_PFanSup_y [W] [min=None, max=None]: Electrical power measurement of supply fan for AHU

floor2_reaAHU_PFreCoi_y [W] [min=None, max=None]: Electrical power measurement of freeze protection coil for AHU

floor2_reaAHU_TCooCoiRet_y [K] [min=None, max=None]: Cooling coil return water temperature measurement for AHU

floor2_reaAHU_TCooCoiSup_y [K] [min=None, max=None]: Cooling coil supply water temperature measurement for AHU

floor2_reaAHU_TFreCoiLea_y [K] [min=None, max=None]: Temperature of air leaving freeze protection coil

floor2_reaAHU_TMix_y [K] [min=None, max=None]: Mixed air temperature measurement for AHU

floor2_reaAHU_TRet_y [K] [min=None, max=None]: Return air temperature measurement for AHU

floor2_reaAHU_TSup_y [K] [min=None, max=None]: Supply air temperature measurement for AHU

floor2_reaAHU_V_flowOA_y [m3/s] [min=None, max=None]: Supply outdoor airflow rate measurement for AHU

floor2_reaAHU_V_flowRet_y [m3/s] [min=None, max=None]: Return air flowrate measurement for AHU

floor2_reaAHU_V_flowSup_y [m3/s] [min=None, max=None]: Supply air flowrate measurement for AHU

floor2_reaAHU_dp_y [Pa] [min=None, max=None]: Static pressure of supply fan for AHU

floor2_reaAHU_occ_y [1] [min=None, max=None]: Occupancy status (1 occupied, 0 unoccupied)

floor2_reaAHU_phiAHURet_y [1] [min=None, max=None]: Return air relative humidity for AHU

floor2_reaAHU_phiAHUSup_y [1] [min=None, max=None]: Supply air relative humidity for AHU

floor2_reaAHU_yCooVal_y [1] [min=None, max=None]: AHU cooling coil valve position measurement

floor2_reaAHU_yOA_y [1] [min=None, max=None]: AHU OA damper position measurement

floor2_reaZonCor_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone mid_floor_cor

floor2_reaZonCor_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone mid_floor_cor

floor2_reaZonCor_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone mid_floor_cor

floor2_reaZonCor_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone mid_floor_cor

floor2_reaZonCor_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone mid_floor_cor

floor2_reaZonCor_yDam_y [1] [min=None, max=None]: Damper position measurement for zone mid_floor_cor

floor2_reaZonCor_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone mid_floor_cor

floor2_reaZonEas_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone mid_floor_eas

floor2_reaZonEas_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone mid_floor_eas

floor2_reaZonEas_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone mid_floor_eas

floor2_reaZonEas_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone mid_floor_eas

floor2_reaZonEas_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone mid_floor_eas

floor2_reaZonEas_yDam_y [1] [min=None, max=None]: Damper position measurement for zone mid_floor_eas

floor2_reaZonEas_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone mid_floor_eas

floor2_reaZonNor_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone mid_floor_nor

floor2_reaZonNor_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone mid_floor_nor

floor2_reaZonNor_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone mid_floor_nor

floor2_reaZonNor_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone mid_floor_nor

floor2_reaZonNor_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone mid_floor_nor

floor2_reaZonNor_yDam_y [1] [min=None, max=None]: Damper position measurement for zone mid_floor_nor

floor2_reaZonNor_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone mid_floor_nor

floor2_reaZonSou_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone mid_floor_sou

floor2_reaZonSou_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone mid_floor_sou

floor2_reaZonSou_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone mid_floor_sou

floor2_reaZonSou_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone mid_floor_sou

floor2_reaZonSou_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone mid_floor_sou

floor2_reaZonSou_yDam_y [1] [min=None, max=None]: Damper position measurement for zone mid_floor_sou

floor2_reaZonSou_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone mid_floor_sou

floor2_reaZonWes_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone mid_floor_wes

floor2_reaZonWes_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone mid_floor_wes

floor2_reaZonWes_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone mid_floor_wes

floor2_reaZonWes_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone mid_floor_wes

floor2_reaZonWes_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone mid_floor_wes

floor2_reaZonWes_yDam_y [1] [min=None, max=None]: Damper position measurement for zone mid_floor_wes

floor2_reaZonWes_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone mid_floor_wes

floor3_reaAHU_CO2_AHUFre_y [ppm] [min=None, max=None]: Fresh air CO2 measurement for AHU

floor3_reaAHU_CO2_AHURet_y [ppm] [min=None, max=None]: Return air CO2 measurement for AHU

floor3_reaAHU_CO2_AHUSup_y [ppm] [min=None, max=None]: Supply air CO2 measurement for AHU

floor3_reaAHU_PFanRet_y [W] [min=None, max=None]: Electrical power measurement of return fan for AHU

floor3_reaAHU_PFanSup_y [W] [min=None, max=None]: Electrical power measurement of supply fan for AHU

floor3_reaAHU_PFreCoi_y [W] [min=None, max=None]: Electrical power measurement of freeze protection coil for AHU

floor3_reaAHU_TCooCoiRet_y [K] [min=None, max=None]: Cooling coil return water temperature measurement for AHU

floor3_reaAHU_TCooCoiSup_y [K] [min=None, max=None]: Cooling coil supply water temperature measurement for AHU

floor3_reaAHU_TFreCoiLea_y [K] [min=None, max=None]: Temperature of air leaving freeze protection coil

floor3_reaAHU_TMix_y [K] [min=None, max=None]: Mixed air temperature measurement for AHU

floor3_reaAHU_TRet_y [K] [min=None, max=None]: Return air temperature measurement for AHU

floor3_reaAHU_TSup_y [K] [min=None, max=None]: Supply air temperature measurement for AHU

floor3_reaAHU_V_flowOA_y [m3/s] [min=None, max=None]: Supply outdoor airflow rate measurement for AHU

floor3_reaAHU_V_flowRet_y [m3/s] [min=None, max=None]: Return air flowrate measurement for AHU

floor3_reaAHU_V_flowSup_y [m3/s] [min=None, max=None]: Supply air flowrate measurement for AHU

floor3_reaAHU_dp_y [Pa] [min=None, max=None]: Static pressure of supply fan for AHU

floor3_reaAHU_occ_y [1] [min=None, max=None]: Occupancy status (1 occupied, 0 unoccupied)

floor3_reaAHU_phiAHURet_y [1] [min=None, max=None]: Return air relative humidity for AHU

floor3_reaAHU_phiAHUSup_y [1] [min=None, max=None]: Supply air relative humidity for AHU

floor3_reaAHU_yCooVal_y [1] [min=None, max=None]: AHU cooling coil valve position measurement

floor3_reaAHU_yOA_y [1] [min=None, max=None]: AHU OA damper position measurement

floor3_reaZonCor_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone top_floor_cor

floor3_reaZonCor_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone top_floor_cor

floor3_reaZonCor_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone top_floor_cor

floor3_reaZonCor_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone top_floor_cor

floor3_reaZonCor_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone top_floor_cor

floor3_reaZonCor_yDam_y [1] [min=None, max=None]: Damper position measurement for zone top_floor_cor

floor3_reaZonCor_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone top_floor_cor

floor3_reaZonEas_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone top_floor_eas

floor3_reaZonEas_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone top_floor_eas

floor3_reaZonEas_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone top_floor_eas

floor3_reaZonEas_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone top_floor_eas

floor3_reaZonEas_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone top_floor_eas

floor3_reaZonEas_yDam_y [1] [min=None, max=None]: Damper position measurement for zone top_floor_eas

floor3_reaZonEas_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone top_floor_eas

floor3_reaZonNor_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone top_floor_nor

floor3_reaZonNor_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone top_floor_nor

floor3_reaZonNor_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone top_floor_nor

floor3_reaZonNor_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone top_floor_nor

floor3_reaZonNor_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone top_floor_nor

floor3_reaZonNor_yDam_y [1] [min=None, max=None]: Damper position measurement for zone top_floor_nor

floor3_reaZonNor_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone top_floor_nor

floor3_reaZonSou_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone top_floor_sou

floor3_reaZonSou_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone top_floor_sou

floor3_reaZonSou_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone top_floor_sou

floor3_reaZonSou_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone top_floor_sou

floor3_reaZonSou_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone top_floor_sou

floor3_reaZonSou_yDam_y [1] [min=None, max=None]: Damper position measurement for zone top_floor_sou

floor3_reaZonSou_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone top_floor_sou

floor3_reaZonWes_CO2Zon_y [ppm] [min=None, max=None]: Zone air CO2 measurement for zone top_floor_wes

floor3_reaZonWes_TSup_y [K] [min=None, max=None]: Discharge air temperature measurement for zone top_floor_wes

floor3_reaZonWes_TZon_y [K] [min=None, max=None]: Zone air temperature measurement for zone top_floor_wes

floor3_reaZonWes_V_flowSet_y [m3/s] [min=None, max=None]: Zone airflow setpoint for zone top_floor_wes

floor3_reaZonWes_V_flow_y [m3/s] [min=None, max=None]: Air flowrate measurement for zone top_floor_wes

floor3_reaZonWes_yDam_y [1] [min=None, max=None]: Damper position measurement for zone top_floor_wes

floor3_reaZonWes_yReheaVal_y [1] [min=None, max=None]: Reheat valve position measurement for zone top_floor_wes

reaChiWatSys_TCHWRet_y [K] [min=None, max=None]: Chilled water return temperature measurement

reaChiWatSys_TCHWSup_y [K] [min=None, max=None]: Chilled water supply temperature measurement

reaChiWatSys_dp_y [Pa] [min=None, max=None]: Differential pressure of chilled water plant measurement

reaChiWatSys_mCHWTot_y [kg/s] [min=None, max=None]: Total chilled water mass flow rate

reaChiWatSys_reaPChi_y [W] [min=None, max=None]: Multiple chiller power consumption

reaChiWatSys_reaPCooTow_y [W] [min=None, max=None]: Multiple cooling tower power consumption

reaChiWatSys_reaPPum_y [W] [min=None, max=None]: Chilled water plant pump power consumption

reaHotWatSys_THWRet_y [K] [min=None, max=None]: Hot water return temperature measurement

reaHotWatSys_THWSup_y [K] [min=None, max=None]: Hot water supply temperature measurement

reaHotWatSys_dp_y [Pa] [min=None, max=None]: Differential pressure of hot water plant measurement

reaHotWatSys_mHWTot_y [kg/s] [min=None, max=None]: Total hot water mass flow rate

reaHotWatSys_reaPBoi_y [W] [min=None, max=None]: Multiple gas boiler power consumption

reaHotWatSys_reaPPum_y [W] [min=None, max=None]: Hot water plant pump power consumption

weaSta_reaWeaCeiHei_y [m] [min=None, max=None]: Cloud cover ceiling height measurement

weaSta_reaWeaCloTim_y [s] [min=None, max=None]: Day number with units of seconds

weaSta_reaWeaHDifHor_y [W/m2] [min=None, max=None]: Horizontal diffuse solar radiation measurement

weaSta_reaWeaHDirNor_y [W/m2] [min=None, max=None]: Direct normal radiation measurement

weaSta_reaWeaHGloHor_y [W/m2] [min=None, max=None]: Global horizontal solar irradiation measurement

weaSta_reaWeaHHorIR_y [W/m2] [min=None, max=None]: Horizontal infrared irradiation measurement

weaSta_reaWeaLat_y [rad] [min=None, max=None]: Latitude of the location

weaSta_reaWeaLon_y [rad] [min=None, max=None]: Longitude of the location

weaSta_reaWeaNOpa_y [1] [min=None, max=None]: Opaque sky cover measurement

weaSta_reaWeaNTot_y [1] [min=None, max=None]: Sky cover measurement

weaSta_reaWeaPAtm_y [Pa] [min=None, max=None]: Atmospheric pressure measurement

weaSta_reaWeaRelHum_y [1] [min=None, max=None]: Outside relative humidity measurement

weaSta_reaWeaSolAlt_y [rad] [min=None, max=None]: Solar altitude angle measurement

weaSta_reaWeaSolDec_y [rad] [min=None, max=None]: Solar declination angle measurement

weaSta_reaWeaSolHouAng_y [rad] [min=None, max=None]: Solar hour angle measurement

weaSta_reaWeaSolTim_y [s] [min=None, max=None]: Solar time

weaSta_reaWeaSolZen_y [rad] [min=None, max=None]: Solar zenith angle measurement

weaSta_reaWeaTBlaSky_y [K] [min=None, max=None]: Black-body sky temperature measurement

weaSta_reaWeaTDewPoi_y [K] [min=None, max=None]: Dew point temperature measurement

weaSta_reaWeaTDryBul_y [K] [min=None, max=None]: Outside drybulb temperature measurement

weaSta_reaWeaTWetBul_y [K] [min=None, max=None]: Wet bulb temperature measurement

weaSta_reaWeaWinDir_y [rad] [min=None, max=None]: Wind direction measurement

weaSta_reaWeaWinSpe_y [m/s] [min=None, max=None]: Wind speed measurement

EmissionsElectricPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh of electricity

EmissionsGasPower [kgCO2/kWh]: Kilograms of carbon dioxide to produce 1 kWh thermal from gas

HDifHor [W/m2]: Horizontal diffuse solar radiation

HDirNor [W/m2]: Direct normal radiation

HGloHor [W/m2]: Horizontal global radiation

HHorIR [W/m2]: Horizontal infrared irradiation

InternalGainsCon[bot_floor_cor] [W]: Convective internal gains of zone

InternalGainsCon[bot_floor_eas] [W]: Convective internal gains of zone

InternalGainsCon[bot_floor_nor] [W]: Convective internal gains of zone

InternalGainsCon[bot_floor_sou] [W]: Convective internal gains of zone

InternalGainsCon[bot_floor_wes] [W]: Convective internal gains of zone

InternalGainsCon[mid_floor_cor] [W]: Convective internal gains of zone

InternalGainsCon[mid_floor_eas] [W]: Convective internal gains of zone

InternalGainsCon[mid_floor_nor] [W]: Convective internal gains of zone

InternalGainsCon[mid_floor_sou] [W]: Convective internal gains of zone

InternalGainsCon[mid_floor_wes] [W]: Convective internal gains of zone

InternalGainsCon[top_floor_cor] [W]: Convective internal gains of zone

InternalGainsCon[top_floor_eas] [W]: Convective internal gains of zone

InternalGainsCon[top_floor_nor] [W]: Convective internal gains of zone

InternalGainsCon[top_floor_sou] [W]: Convective internal gains of zone

InternalGainsCon[top_floor_wes] [W]: Convective internal gains of zone

InternalGainsLat[bot_floor_cor] [W]: Latent internal gains of zone

InternalGainsLat[bot_floor_eas] [W]: Latent internal gains of zone

InternalGainsLat[bot_floor_nor] [W]: Latent internal gains of zone

InternalGainsLat[bot_floor_sou] [W]: Latent internal gains of zone

InternalGainsLat[bot_floor_wes] [W]: Latent internal gains of zone

InternalGainsLat[mid_floor_cor] [W]: Latent internal gains of zone

InternalGainsLat[mid_floor_eas] [W]: Latent internal gains of zone

InternalGainsLat[mid_floor_nor] [W]: Latent internal gains of zone

InternalGainsLat[mid_floor_sou] [W]: Latent internal gains of zone

InternalGainsLat[mid_floor_wes] [W]: Latent internal gains of zone

InternalGainsLat[top_floor_cor] [W]: Latent internal gains of zone

InternalGainsLat[top_floor_eas] [W]: Latent internal gains of zone

InternalGainsLat[top_floor_nor] [W]: Latent internal gains of zone

InternalGainsLat[top_floor_sou] [W]: Latent internal gains of zone

InternalGainsLat[top_floor_wes] [W]: Latent internal gains of zone

InternalGainsRad[bot_floor_cor] [W]: Radiative internal gains of zone

InternalGainsRad[bot_floor_eas] [W]: Radiative internal gains of zone

InternalGainsRad[bot_floor_nor] [W]: Radiative internal gains of zone

InternalGainsRad[bot_floor_sou] [W]: Radiative internal gains of zone

InternalGainsRad[bot_floor_wes] [W]: Radiative internal gains of zone

InternalGainsRad[mid_floor_cor] [W]: Radiative internal gains of zone

InternalGainsRad[mid_floor_eas] [W]: Radiative internal gains of zone

InternalGainsRad[mid_floor_nor] [W]: Radiative internal gains of zone

InternalGainsRad[mid_floor_sou] [W]: Radiative internal gains of zone

InternalGainsRad[mid_floor_wes] [W]: Radiative internal gains of zone

InternalGainsRad[top_floor_cor] [W]: Radiative internal gains of zone

InternalGainsRad[top_floor_eas] [W]: Radiative internal gains of zone

InternalGainsRad[top_floor_nor] [W]: Radiative internal gains of zone

InternalGainsRad[top_floor_sou] [W]: Radiative internal gains of zone

InternalGainsRad[top_floor_wes] [W]: Radiative internal gains of zone

LowerSetp[bot_floor_cor] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[bot_floor_eas] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[bot_floor_nor] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[bot_floor_sou] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[bot_floor_wes] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[mid_floor_cor] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[mid_floor_eas] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[mid_floor_nor] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[mid_floor_sou] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[mid_floor_wes] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[top_floor_cor] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[top_floor_eas] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[top_floor_nor] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[top_floor_sou] [K]: Lower temperature set point for thermal comfort of zone

LowerSetp[top_floor_wes] [K]: Lower temperature set point for thermal comfort of zone

Occupancy[bot_floor_cor] [number of people]: Number of occupants of zone

Occupancy[bot_floor_eas] [number of people]: Number of occupants of zone

Occupancy[bot_floor_nor] [number of people]: Number of occupants of zone

Occupancy[bot_floor_sou] [number of people]: Number of occupants of zone

Occupancy[bot_floor_wes] [number of people]: Number of occupants of zone

Occupancy[mid_floor_cor] [number of people]: Number of occupants of zone

Occupancy[mid_floor_eas] [number of people]: Number of occupants of zone

Occupancy[mid_floor_nor] [number of people]: Number of occupants of zone

Occupancy[mid_floor_sou] [number of people]: Number of occupants of zone

Occupancy[mid_floor_wes] [number of people]: Number of occupants of zone

Occupancy[top_floor_cor] [number of people]: Number of occupants of zone

Occupancy[top_floor_eas] [number of people]: Number of occupants of zone

Occupancy[top_floor_nor] [number of people]: Number of occupants of zone

Occupancy[top_floor_sou] [number of people]: Number of occupants of zone

Occupancy[top_floor_wes] [number of people]: Number of occupants of zone

PriceElectricPowerConstant [($/Euro)/kWh]: Completely constant electricity price

PriceElectricPowerDynamic [($/Euro)/kWh]: Electricity price for a day/night tariff

PriceElectricPowerHighlyDynamic [($/Euro)/kWh]: Spot electricity price

PriceGasPower [($/Euro)/kWh]: Price to produce 1 kWh thermal from gas

TBlaSky [K]: Black Sky temperature

TDewPoi [K]: Dew point temperature

TDryBul [K]: Dry bulb temperature at ground level

TWetBul [K]: Wet bulb temperature

UpperCO2[bot_floor_cor] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[bot_floor_eas] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[bot_floor_nor] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[bot_floor_sou] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[bot_floor_wes] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[mid_floor_cor] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[mid_floor_eas] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[mid_floor_nor] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[mid_floor_sou] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[mid_floor_wes] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[top_floor_cor] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[top_floor_eas] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[top_floor_nor] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[top_floor_sou] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperCO2[top_floor_wes] [ppm]: Upper CO2 set point for indoor air quality of zone

UpperSetp[bot_floor_cor] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[bot_floor_eas] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[bot_floor_nor] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[bot_floor_sou] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[bot_floor_wes] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[mid_floor_cor] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[mid_floor_eas] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[mid_floor_nor] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[mid_floor_sou] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[mid_floor_wes] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[top_floor_cor] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[top_floor_eas] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[top_floor_nor] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[top_floor_sou] [K]: Upper temperature set point for thermal comfort of zone

UpperSetp[top_floor_wes] [K]: Upper temperature set point for thermal comfort of zone

ceiHei [m]: Ceiling height

cloTim [s]: One-based day number in seconds

lat [rad]: Latitude of the location

lon [rad]: Longitude of the location

nOpa [1]: Opaque sky cover [0, 1]

nTot [1]: Total sky Cover [0, 1]

pAtm [Pa]: Atmospheric pressure

relHum [1]: Relative Humidity

solAlt [rad]: Altitude angel

solDec [rad]: Declination angle

solHouAng [rad]: Solar hour angle.

solTim [s]: Solar time

solZen [rad]: Zenith angle

winDir [rad]: Wind direction

winSpe [m/s]: Wind speed

Lighting heat gain is included in the internal heat gains and is not controllable.

There is no shading on this building.

There is no onsite generation or storage on this building site.

Building internal mass is modeled in EnergyPlus using two approaches: the InternalMass object and the Zone Air Capacitance Multiplier. Internal mass surface area values are taken from the DOE Reference Buildings, and a zone air capacitance multiplier of 8 is applied to represent typical internal-mass levels (Chen et al., 2022).

Chen, Z. , Wen, J. , Bushby, S. , Lo, L. , O'Neill, Z. , Payne, V. , Pertzborn, A. , Calfa, C. , Fu, Y. , Grajewski, G. , Li, Y. and Yang, Z. (2022), An Analysis of the Hybrid Internal Mass Modeling Approach in EnergyPlus, Proceedings of eSim 2022: 12th Conference of IBPSA-Canada, Ottawa, CA, [online] , https://tsapps.nist.gov/publication/get_pdf.cfm?pub_id=934193 (Accessed September 12, 2025)A moist air model is used. Relative humidity is tracked based on latent heat gain from occupants, outside air relative humidity, and a cooling coil model that includes condensation.

The duct airflow and chilled/hot water hydronic loop are modeled using a pressure-flow network. No air exchange between zones.

Air infiltration features have been incorporated into the exterior zones on all the floors. The specified infiltration rate (m_flow_infAir) is based on an air leakage rate of 1 cfm/ft² of exterior surface area, measured at a constant building pressure differential of 75 Pa. This value is then converted to a wind-driven infiltration rate at a reference wind speed of 4.47 m/s, following the methodology outlined in ASHRAE Standard 90.1-2022, Section G3.2.1.7. During the occupied hours, the infiltration schedule uses a fraction of 0.25 to approximate the reduced infiltration rate resulting from mechanical ventilation being active. This assumption aligns with the modeling rules in Appendix C of ASHRAE Standard 90.1-2022. Additionally, the infiltration rate is dynamically adjusted to account for variations in wind speed.

CO2 generation is 0.0048 L/s per person (Table 5, Persily and De Jonge 2017) and density of CO2 assumed to be 1.8 kg/m3, making CO2 generation 8.64e-6 kg/s per person. Outside air CO2 concentration is 400 ppm.

Persily, A. and De Jonge, L. (2017). Carbon dioxide generation rates for building occupants. Indoor Air, 27, 868–879. https://doi.org/10.1111/ina.12383.

The Peak Heat Day (specifier for /scenario API is 'peak_heat_day') period is:

The Typical Heat Day (specifier for /scenario API is 'typical_heat_day') period is:

The Peak Cool Day (specifier for /scenario API is 'peak_cool_day') period is:

The Typical Cool Day (specifier for /scenario API is 'typical_cool_day') period is:

The Mix Day (specifier for /scenario API is 'mix_day') period is:

Constant electricity prices are based on those from ComEd [1], the utility serving the greater Chicago area. The price is based on the Basic Electricity Service (BES) rate provided to the Watt-Hour customer class for applicable charges per kWh. This calculation is an approximation to obtain a reasonable estimate of price. The charges included are as follows:

The total constant electricity price is $0.094/kWh

Dynamic electricity prices are based on those from ComEd [1], the utility serving the greater Chicago area. The price is based on the Residential Time of Use Pricing Pilot (RTOUPP) rate for applicable charges per kWh. This calculation is an approximation to obtain a reasonable estimate of dynamic price. The charges included are the same as the constant scenario (using BES) except for the following change:

Summer (Jun, Jul, Aug, Sep):

Highly Dynamic electricity prices are based on those from ComEd [1], the utility serving the greater Chicago area. The price is based on the Basic Electric Service Hourly Pricing (BESH) rate for applicable charges per kWh. This calculation is an approximation to obtain a reasonable estimate of highly dynamic price. The charges included are the same as the constant scenario (using BES) except for the following change:

Gas price is assumed constant and of 0.024 $/kWh as obtained from the Nicor Gas for Jan. 2023 https://www.icc.illinois.gov/natural-gas-choice/purchased-gas-adjustment-rates (accessed on Aug 2023).

References:

The Electricity Emissions Factor profile is based on the average annual emissions from 2019 for the state of Illinois, USA per the EIA. It is 752 lbs/MWh or 0.341 kgCO2/kWh. For reference, see https://www.eia.gov/electricity/state/illinois/